OUR MANUFACTURING PROCESSES

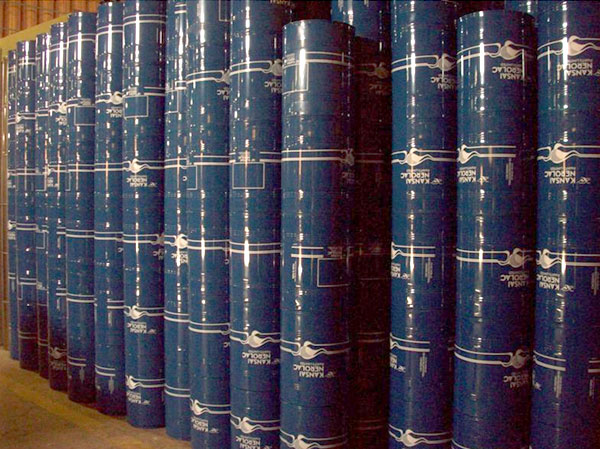

An area of approx. 6000 sq.ft has been reserved for the finished goods storage against regular contract orders are ready for despatch ATN ( any time needed basis ). This area is over and above the storage place for raw materials and packing materials. This existing area accommodates approx 10,000 to 12,000 drums. The stores functioning is controlled by the procurement department.

Lacquered drums/ barrels are recommended to pack particularly highly corrosive and hazardous type of product. Suvida has an extremely different system of epoxy coating and hence the epoxy quality at Suvida is different from others. The use of best quality coating material and the baking at the required temperatures, finally gives top class look, performance and better resistance for a long period. The lacquered in-house system is created and controlled by our experts. This is one of the speciality jobs that we provide to the customer.